Key Attributes of Our Quality Management:

- Comprehensive Traceability: Detailed documentation ensuring traceability from material procurement to final product.

- Standardized Certification: Clearly structured 3.1 certificates capturing essential quality data.

- Continuous Skill Development: Regular training programs maintaining a highly skilled and knowledgeable workforce.

- Secure Supply Chain: Advanced supply chain management practices guaranteeing consistency and reliability.

- Expert Inspections: Specialized professionals conducting detailed quality assessments and tests.

Advanced Testing Capabilities

Raajratna Stainless Pvt. Ltd. employs state-of-the-art testing methods to guarantee our stainless steel tubes meet the highest standards of quality, safety, and performance. Our rigorous testing processes help identify and eliminate potential defects, ensuring reliability and excellence for diverse industrial applications.

Chemical Composition

| Grade | UNS Number | Carbon (C) Max. | Manga nese (Mn) Max. | Phos phorous (P) Max. | Sulphur (S) Max. | Silicon (Si) Max. | Chromium (Cr) | Nickel (Ni) | Molub denum (Mo) | Nitrogen (N) | Copper (Cu) |

| Austenitic Stainless Steel | |||||||||||

| 304 | S30400 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-11.00 | — | 0.10 | – |

| 304L | S30403 | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 18.0-20.0 | 8.0-12.0 | — | 0.10 | – |

| 316 | S31600 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.10 | – |

| 316L | S31603 | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.10 | – |

| 904L | N08904 | 0.02 | 2.00 | 0.040 | 0.030 | 1.00 | 19.0-23.0 | 23.0-28.0 | 4.00-5.00 | 0.10 | 1.00-2.00 |

| 1.4301 | — | 0.07 | 2.00 | 0.045 | 0.015 | 1.00 | 17.5-19.5 | 8.0-10.5 | — | 0.10 | – |

| 1.4307 | — | 0.03 | 2.00 | 0.045 | 0.015 | 1.00 | 17.5-19.5 | 8.0-10.5 | — | 0.10 | – |

| 316Lcs / 1.4404 | — | 0.03 | 2.00 | 0.045 | 0.005-0.017 | 1.00 | 16.5-18.5 | 10.0-13.0 | 2.00-2.50 | 0.10 | – |

| 1.4435 | — | 0.03 | 2.00 | 0.045 | 0.015-0.017 | 1.00 | 17.0-19.0 | 12.5-15.0 | 2.50-3.00 | 0.10 | – |

| 1.4539 | — | 0.02 | 2.00 | 0.030 | 0.010 | 0.70 | 19.0-21.0 | 24.0-26.0 | 4.00-5.00 | 0.10 | 1.00-2.00 |

| Duplex Stainless Steel | |||||||||||

| Duplex 2205 | S32205 | 0.03 | 2.00 | 0.03 | 0.02 | 1.00 | 22.0-23.0 | 4.50-6.50 | 3.00-3.50 | 0.10 | – |

| Lean Duplex 2101 | S32101 | 0.04 | 4.0-6.0 | 0.04 | 0.03 | 1.00 | 21.0-22.0 | 1.35-1.70 | 0.10-0.80 | 0.20-0.25 | 0.10-0.80 |

| Lean Duplex 2304 | S32304 | 0.03 | 2.50 | 0.04 | 0.04 | 1.00 | 21.5-24.5 | 3.00-5.50 | 0.05-0.60 | 0.05-0.20 | 0.05-0.60 |

Titanium Alloy Steel

| Grade | Nitrogen (N) Max. | Carbon (C) Max. | Hydrogen (H) Max. | Iron (Fe) Max. | Oxygen (O) Max. | AL | V | Pa | Ma | Ni | Others |

| Grade 1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | – | – | – | – | – | – |

| Grade 2 | 0.03 | 0.08 | 0.015 | 0.20 | 0.25 | – | – | – | — | – | – |

Experience Quality That Defines Excellence

Other Tests

- 100% visual & dimension inspection

- ID surface roughness measurements

- Corner cut measurements

- Weld decay test

- Micro Test (Grain Size Number)

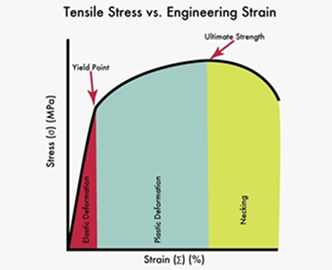

Mechanical Properties

| Grade | UNS Number | ASTM Specificaon | Tensile Strength Min. (Mpa) | Yield Strength Min (Mpa) | Elongation(%) (Min.) | Hardness (Max.) |

| Austenitic Welded Stainless Steel | ||||||

| 304 | S30400 | ASTM A270 / A249 / A269 | 515 | 205 | 35 | 90 HRB |

| 304L | S30403 | ASTM A270 / A249 / A269 | 485 | 170 | 35 | 90 HRB |

| 316 | S31600 | ASTM A270 / A249 / A269 | 515 | 205 | 35 | 90 HRB |

| 316L | S31603 | ASTM A270 / A249 / A269 | 485 | 170 | 35 | 90 HRB |

| 904L | N08904 | ASTM 249 | 490 | 215 | 35 | 90 HRB |

| 1.4307 | — | EN 10217-7 | 470-670 | 180 | 40 | — |

| 1.4404 | — | EN 10217-7 | 490-690 | 190 | 40 | — |

| 1.4435 | — | EN 10217-7 | 490-690 | 190 | 40 | — |

| 1.4539 | — | EN 10217-7 | 520-720 | 220 | 35 | — |

| Duplex Welded Stainless Steel | ||||||

| Duplex 2205 | S32205 | ASTM 789 / A790 | 655 | 485 | 25 | 30 HRC |

| Lean Duplex 2101 | S32101 | A789 | 700 | 530 | 30 | 30 HRC |

| Lean Duplex 2304 | S32304 | ASTM 789 / A790 | 620 | 485 | 30 | 30 HRC |

Titanium Welded Tubes

| Grade | UNS Number | ASTM Specification | Resistanceto Traction (Mpa) | Tensile Strength (Mpa) | Elongation(%) (Min.) |

| Grade 1 | R50250 | ASTM B 338 | 240 | 170 | 24 |

| Grade 2 | R50400 | ASTM B 338 | 345 | 275 | 20 |

Product Finish Specification

| Process Designation | Equivalent to | Surface Treatment | Inside Surface Finish Value (Ra) | ||

| Outer Surface | Inner Surface | μ-ln (max) | μ-m (max) | ||

| BA – BA | SF0 | Bright Annealed | Bright Annealed | – | – |

| MP – BA | SF3 | Mechanical Polished | Bright Annealed | 30 | ≤ 0.76 |

| MP – MP | SF2 | Mechanical Polished | Mechanical Polished | 25 | ≤ 0.64 |

| SF1 | 20 | ≤ 0.51 | |||

| MP – EP | SF4 | Mechanical Polished | Electro Polished | 15 | ≤ 0.38 |

| SF5 | 20 | ≤ 0.51 | |||

| SF6 | 25 | ≤ 0.64 | |||

Stainless Steel Tubes Packing

We Provide packaging solutions that guarantee the integrity of products during transport, storage, and handling:

Durable, sustainable, and protective packaging solution offering superior protection and ease of handling.

Robust, space-efficient packaging designed specifically to ensure tube integrity and simplify stacking and transport logistics.

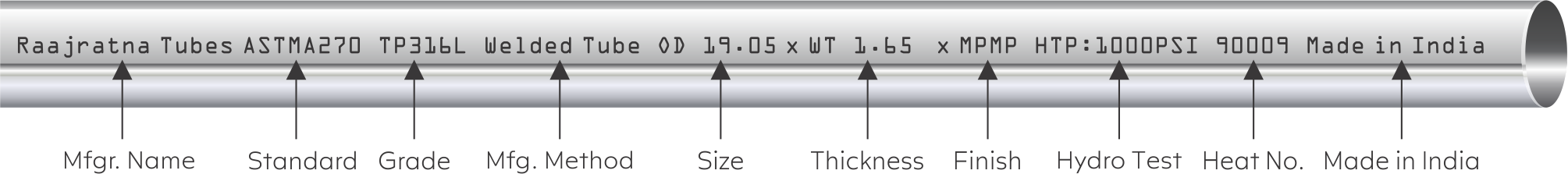

Tube Marking Information

Each stainless steel tube is clearly marked with essential identification details to ensure full transparency and ease of traceability:

| Mfgr. Name | Standard | Grade | Mfg. Method | Size | Thickness | Finish | Hydro Test | Heat No. | Made in India |

| Raajratna Stainless Pvt. Ltd. | ASTM A270 | TP316L | Welded Tube | OD 19.05 | WT 1.65 | MPMP | HTP:1000PSI | 90009 | Made in India |